Mastering SDVs: Why innovative CTOs and R&D Teams turn to Agentic Engineering Intelligence

By the time he reaches his office, he's uneasy. Disconnected systems and scattered data could mean hours of chasing down teams, reviewing outdated spreadsheets, or reconciling conflicting reports. The model line responsible might not get the clarity he needs before his presentation to the Board. Worse, his credibility—and the company's—may take a hit if gaps in the roadmap are exposed.

While the specific scenario may vary from company to company, the core challenge remains universal: Software-defined vehicles (SDVs) are changing the automotive industry, but they bring with them an exponential increase in complexity. Companies like Tesla and NIO are leading the charge by rolling out vehicles with continuous updates, where software is the heartbeat of innovation - and with that product complexity continues to grow at unprecedented pace. Engineers are now in charge of understanding not only mechanical but also E/E and SW interdependencies in ever more complex SDV vehicle architectures.

Engineers held back by disconnected engineering systems and fragmented data

Despite advances in vehicle technology, many engineers find themselves slowed down by dispersed or conflicting data across many non-connected systems, PowerPoint or Excel files, spending between a third and half of their time on reconciling information across these sources (according to a survey we recently conducted).

For a CTO this disarray trickles upward: without real-time visibility into true feature maturity or cross-functional dependencies, executive decision-making becomes reactive rather than strategic. This situation prevents everyone from focusing on innovation and problem-solving – “Where shall I even begin?”.

This problem extends to the shop floor, where production planning suffers from misaligned data, and to the Aftermarket, where service teams struggle with siloed information. In every scenario, the inability to unify and interlink data leads to delays, errors, and missed opportunities for innovation. This status quo is no longer sustainable.

A treasure that can make a difference: Unstructured data

To get the full engineering context needed to lay the foundation to do so, the key lies in unstructured data – milestones, project data, compliance or specification notes or other forms of information are stored in mails, text documents or PDFs. They don’t neatly fit into traditional data fields.

Picture the CTO returning to his desk, trying to locate the latest specification update for the hands-free assistant. It's buried in a shared drive under a cryptic file name. He calls his engineering lead, only to discover that other teams have been working on conflicting requirements. Hours are spent reconciling this information, and he still doesn’t have a clear answer for his presentation. On top, all these manual processes are error-prone and time-consuming, delaying not only project timelines.

Yet, this is the almost daily reality of more than two thirds of the whole engineering community in automotive, according to a survey SPREAD recently conducted: Handling unstructured data that is hardly inaccessible, disconnected from structured data (like CAD models or BOMs), and hard to locate when needed.

“Either we and you utilize AI and the technology and see it as an opportunity - or other players will put massive pressure on Germany as an industrial location through these efficiency gains, meaning that we will no longer be able to compete.”

So, what if we could turn all unstructured data into structured data and make use of this data treasure manufactures accumulated over past decades? What if we could turn all this data into a unprecedented knowledge advantage?

A common language is needed for that (to enable AI capabilities)

To make real headway in transforming cross-functional engineering workflows, we need a common language that seamlessly bridges structured and unstructured data.

This is how Philipp Noll, Co-Founder of SPREAD puts it:

“A semantic layer is needed that brings together unstructured and structured data in a standardized fashion and makes it easily accessible. The worlds of structured and unstructured data are not yet connected beyond “data monkey” manual data integration. We need to bridge this gap more intelligently and scalable.”

This standardized approach would enable engineers to access all relevant information seamlessly, across all sources and formats, creating a unified view of the entire product lifecycle.

That semantic layer, implemented as a knowledge graph, could provide a common language by structuring and linking scattered data into a cohesive information model. It could reveal relationships and dependencies, making complex connections easier to understand and access for engineering teams. With this layer in place, engineers would gain new insights and unlock the potential of data that was previously fragmented or hidden.

Agentic Engineering Intelligence: Turn your data into a knowledge advantage

Philipp Noll, Co-Founder of SPREAD, recently presented the company's latest technological innovation that provides exactly that kind of solution called Agentic Engineering Intelligence (Agentic EI) – the combination of Knowledge Graph, Digital Twin, and AI.

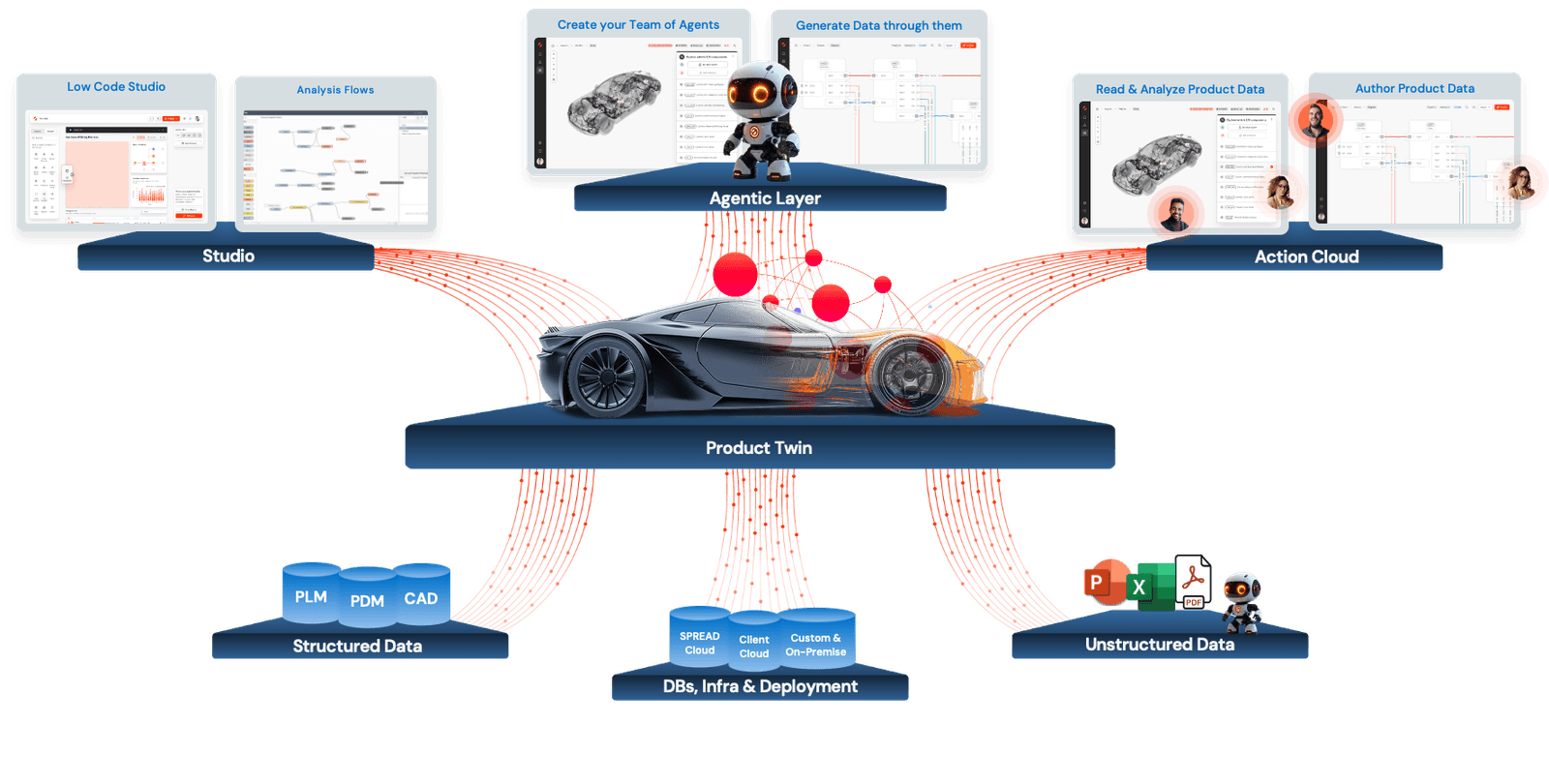

SPREAD has developed Agentic Engineering Intelligence (Agentic EI) as a solution to these data fragmentation challenges. Agentic EI connects structured and unstructured data sources through three core components, enabling engineers to gain a comprehensive view of product data and reduce inefficiencies in the engineering process.

Agentic Engineering Intelligence redefines how engineers harness the potential of data by bridging structured and unstructured formats into a unified, actionable ecosystem. This transformation enables decision-makers like the CTO to extract hidden value from scattered data sources, turning complexity into clarity.

As Philipp Noll, Co-Founder of SPREAD, aptly states:

"We need to see this data as an advantage to become faster and more efficient."

Imagine the CTO receiving a single interactive dashboard powered by Agentic EI. He immediately sees the hands-free driving assistant’s progress: completed milestones, pending compliance requirements, and interdependencies with other vehicle features. This clarity enables him to provide his model line responsible with accurate, real-time insights, ensuring a confident presentation to the board.

This shift is not just about faster access but about creating a seamless interaction between humans and AI. It transforms isolated silos of information into dynamic, intelligent resources that actively assist engineers in solving complex challenges, reducing errors, and enhancing productivity across the product lifecycle.

With access to both structured and unstructured data in a context-rich environment, engineers can now tackle complex tasks, such as creating new data models and configurations, with greater efficiency.

Real-life use cases for Agentic Engineering Intelligence

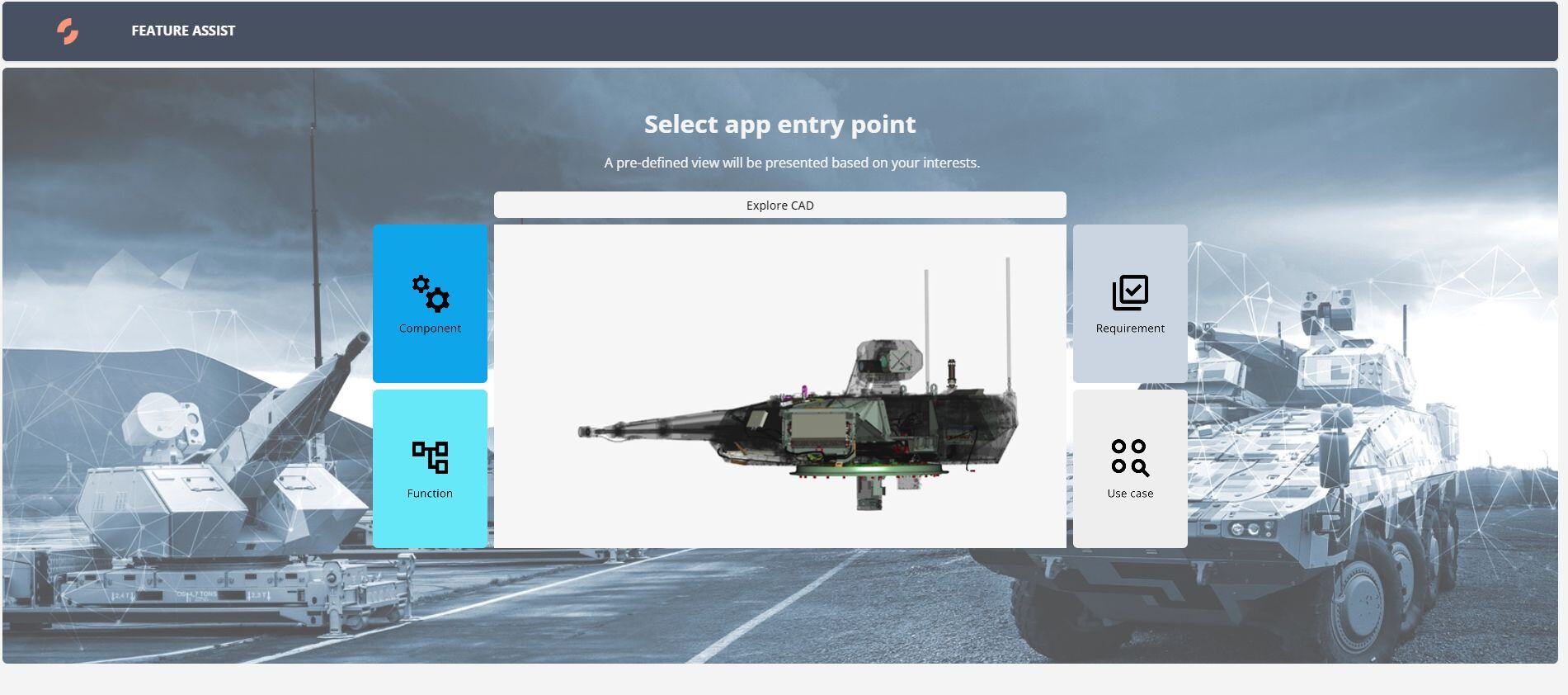

Agentic EI offers a range of applications that deliver real value in automotive development:

- Requirements Management: AI anticipates and resolves conflicting requirements early in the process, preventing costly delays.

- Compliance checks: Regulatory compliance is automatically verified, saving hours of manual work and reducing errors.

- Error Management: AI proactively identifies and addresses potential issues, helping to keep development on track and avoiding late-stage disruptions.

How does it work: The three layers of Agentic EI

Again, at the heart of Agentic EI lies a semantic layer powered by a knowledge graph. This layer structures and links scattered data into a cohesive, queryable model, making it easier for engineering teams to understand complex interdependences.

1. Rapid ingestion layer: Smart connectors for different engineering systems, data and tools

At the foundational layer, SPREAD’s connectors link multiple engineering tools and systems, establishing a continuous data flow that ensures engineers can access the most current, relevant data at all stages of development. This also ensures that the AI agents have continuous access to the most current and relevant information across various stages of product development. By bridging diverse engineering tools, this layer enables a unified data environment.

2. Twin layer: The role of the graph-based Product Twin (PT)

The Product Twin is powered by a robust Knowledge Graph called Engineering Intelligence Graph (EI Graph). It serves as a comprehensive digital twin that captures both real-time and historical data across the entire product lifecycle. This digital twin doesn’t just mirror the product’s physical aspects; it organizes and contextualizes both structured and unstructured data, such as component specifications, maintenance histories, simulation data, and interdependencies.

The EI Graph transforms raw data into a fully interconnected, context-rich network, allowing SPREAD’s AI agents called Engineering Intelligence Agents (EI Agents) to simulate scenarios, anticipate challenges, and deliver actionable insights that are tailored to the lifecycle stage and engineering requirements. By mapping out complex relationships within and across product components, lifecycles, and engineering domains, the PT acts as a single source of truth for SPREAD’s EI Agents.

The result: reliable EI Agents that deliver precise information without hallucinations or inconsistencies. That’s also why they learn faster and are more reliable from the start in comparison to generic all-in-one design AI models.

3. The Action Cloud: Automating tasks and empowering engineers

The Action Cloud supports a wide array of Engineering Intelligence (EI) solutions, each designed to tackle specific challenges across the entire product lifecycle, from R&D to Production, and Aftermarket.

Furthermore, within the Action Cloud, EI Agents perform high-stakes tasks, such as compliance checks, requirements optimization, and information retrieval, with remarkable precision.

These EI agents are specifically taught by expert users to interpret complex engineering queries, enabling them to respond to natural language prompts and proactively assist engineers. These agents use structured and unstructured data, turning into an intelligent repository that enables fast, accurate insights.

Since they are designed to address specific engineering pain points, these agents enhance workflows by proactively providing relevant information, reducing errors, and empowering engineers to validate and refine results for optimized outcomes.

Engineers working with SPREAD EI Agents benefit from e.g.:

- Accelerated problem resolution: By pinpointing and analyzing dependencies, Agentic EI quickly resolves engineering issues that would otherwise delay production.

- Reduced manual workload: Automated compliance checks mean engineers no longer spend hours verifying standards; they can focus on higher-value tasks.

- Seamless change management: When modifications are made, Agentic EI automatically analyzes the impacts across all relevant systems, ensuring seamless updates without disrupting workflow.

- Enhanced knowledge access: Engineers gain instant access to structured and unstructured data, reducing search time and improving decision-making.

For decision-makers like the CTO these capabilities mean not only a seamless Board presentation but also faster development cycles, reduced manual effort for her teams, and fewer surprises down the road.

Realize massive value – become 10x faster with a “knowledge advantage”

Engineers overwhelmingly recognize the potential of AI to simplify complex workflows, unlock hidden data insights, and drive innovation. SPREAD’s Agentic EI enables companies to accelerate development processes by up to ten times. By centralizing and interlinking both structured and unstructured data, the system provides a substantial “knowledge advantage” for its customers – just by making already existing information easily accessible.

This advantage allows engineers and decision-makers like the CTO in the elevator not only to work faster but also to produce higher-quality outcomes, meeting industry demands for speed, accuracy, and cost-effectiveness in engineering. It ensures confident decisions, efficient workflows, and aster time-to-market for groundbreaking technologies like the hands-free driving assistant.

“You're using our technology - we're making sure you're able to structure your information to achieve your goals”